Packing

Phase one

Blocks

01

Blocks

1- In Box Containers : Marble blocks are pushed inside the box container on strong suitable wooden bars using huge fork lifts or using the over head crane together with a heavy strong pushing machine. For easy unloading please contact us at Euro Trade.

2- General Cargo: Marble blocks are placed the way they are directly on the trucks, to

be transported to the port and placed on wooden bars on the board of special

vessels .

3- In Open Top Containers : Blocks are placed inside the open top container on strong suitable wooden bars for easy unloading.

Phase Two

slabs

02

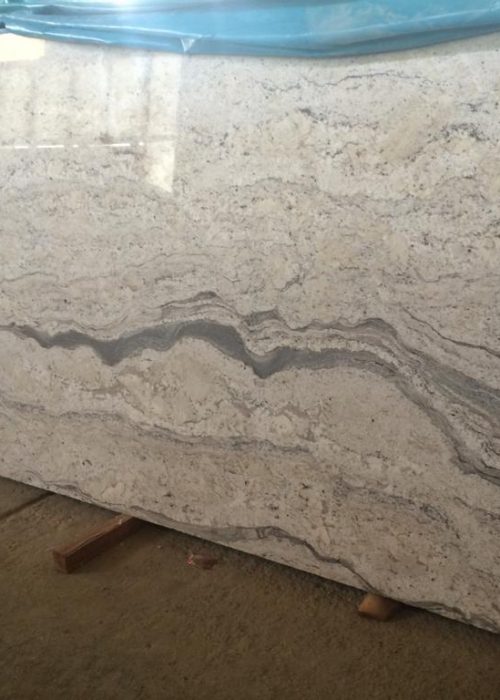

Slabs

1- Wooden Bundle: The slabs are gathered in groups each group contains form 8 to 15 slabs according to their thickness packed in wooded bundles & Loaded either in 20 feet box container using the boom crane or in open container using the over head crane according to the request of our customer as well as the availability of the open top containers. N.B. Polished Slabs are separated by Plastic sheets to be protected against scratches.

2- Slabs Grouping: The Slabs Grouping way of packing is really near from the wooden bundle way of packing, where each bundle (8 to 12 slabs according to the thickness) is separated from the other by two wooden bars and all the bundles are place over another two wooden bars separating the slabs form the ground of the container and this enables our customers to wire each bundle separately, lifting them up by using a boom crane or a fork lift and withdraw it out of the container. The only difference is that you will not be able to unload the container by pulling the bundles out.

3- Slabs Normal Packing: The slabs are manually placed

directly on the ground of the container lashed on two wooden bars (Cavalletos) on the inner long sides of 20 feet dry Box container, if the slabs are long in length so the container take only two groups one to the right and the other to the left, if the slabs are short in length so the container take four group of slabs two to the right and two to the left. N.B. Polished Slabs are separated by Plastic sheets to be protected against scratches. 4- (A) Frame : look at the picture inside open top container

Phase Three

Tiles

03

Tiles

1- Tiles are packed after being highly selected according to the approved samples in wooden crates (Boxes) lined by foam for better protection. Each Wooden crate contains certain Number of tiles according to the thickness, All

the cerate content details are mentioned in the label paper fixed on out side of the crate. Styrofoam boxes Only 12″x12″ tiles (10mm +/- 0.5 thick) are packed in Styrofoam boxes before being packed inside the wooden creates, thin Plastic sheets are added between polished faces of the tiles to avoid surface scratching.

2- Wooden pallet:

Tiles are packed after being highly selected according to the approved samples on wooden pallets surrounded by foam for better protection, and fasten with plastic belts with rubber pieces on the edges to avoid any damages that might happen According to the size & thickness of the tiles each Wooden pallet contains certain number of tiles, All details of the pallet contents are mentioned in the label paper

fixed on the lateral side of the pallet.